Self-standing bag spout manufacturer shares some issues to pay attention to when choosing a self-standing bag packaging machine

Release Date:

2022-05-12

The stand-up pouch packaging machine uses different types of pouches to package various products, including the suction inlet stand-up pouch packaging machine, special-shaped stand-up pouch packaging machine, and pre-made packaging machine. So, before purchasing a stand-up pouch packaging machine, do you know what you need to pay attention to? Below, the stand-up pouch nozzle manufacturer shares some issues to consider when selecting a stand-up pouch packaging machine.

With the increase in the market, purchasing packaging machines has also encountered significant issues. When choosing a packaging machine factory, how should one select a good packaging machine factory? The stand-up pouch packaging machine is used for stand-up pouch packaging, providing a flexible and economical packaging solution. It is suitable for integrated packaging types for filling multiple materials such as granules and powders. The stand-up pouch packaging machine adopts a main machine variable speed system, servo punching, simple and stable adjustment, and uses a PLC positioning module for accurate positioning with minimal pouch error. It can automatically make bags. It fully automates packaging processes such as measuring, filling, and sealing. The stand-up pouch packaging machine uses different forms of pouch types to package various products, including stand-up pouch spout machines, shaped stand-up pouch machines, and pre-made packaging machines. So, before purchasing a stand-up pouch packaging machine, do you know what to pay attention to? See below. Stand-up Pouch Spout Manufacturer shares some issues to pay attention to when selecting a stand-up pouch packaging machine.

1. First, you can investigate the development and background of the stand-up pouch packaging machine manufacturer and see the feedback from purchasing customers. Currently, there is a large amount of information from mechanical manufacturing factories with experience in producing customized mechanical products, as well as design and engineering companies.

2. If inquiring about the seller's risk situation (such as if the seller has been selected), the stand-up pouch spout manufacturer suggests that after the design plan is finalized and before the quotation is confirmed, relevant personnel should hold a discussion and work closely to determine the investment risks and their occurrence conditions.

3. At the same time, when purchasing packaging machines, do not be tempted by low prices, Stand-up Pouch Spout The manufacturer believes that one should think and purchase from multiple perspectives to avoid unnecessary troubles.

Stand-up pouch spout manufacturer shares the production procedure

1. Prepare for installation: horizontal hot bar knife, bottom hot bar knife, reinforced hot bar knife, install stamping device.

2. Thread the film, set EPC, and align with the pleat pattern.

3. Adjust the bottom hot bar knife, input length and size. The position and direction of the knife must be flat. Please ensure the installation of the photoelectric sensor.

Install the bottom film and adjust to the middle fold. Bottom film drilling.

5. Adjust the horizontal hot bar so that the hot bar knife position coincides with the printing position.

6. Adjust and reinforce the heat sealing block, and apply pressure at the 4-layer cross intersection.

7. Adjust the cutting and trimming device.

8. Confirm and adjust the stamping position and heat sealing position at the bottom. Determine and adjust the position of the side heat sealing knife, reinforce the heat sealing block. Check the heat sealing strength and adjust the heat sealing temperature.

Stand-up Pouch Spout Manufacturer discusses production key points

1. The tension of the bottom film should not be too high. Excessive tension causes floor deformation. Generally, the tension is 0.05~0.2mpa.

2. For the first group, the pressure is higher and the temperature is lower. For the second and third groups, use normal temperature and pressure.

3. The spring pressure of the reinforced hot bar block is adjusted to zero, only acting as the weight of the hot bar device.

4. Silicone board hardness is 50; use a 70 board for small heat sealing areas.

5. During the heat sealing process, the round holes on the bottom surface are called ellipses, and the waiting time can be increased by 100 minutes.

6. The speed of making bags is usually 50~100 pieces per minute.

Keywords:

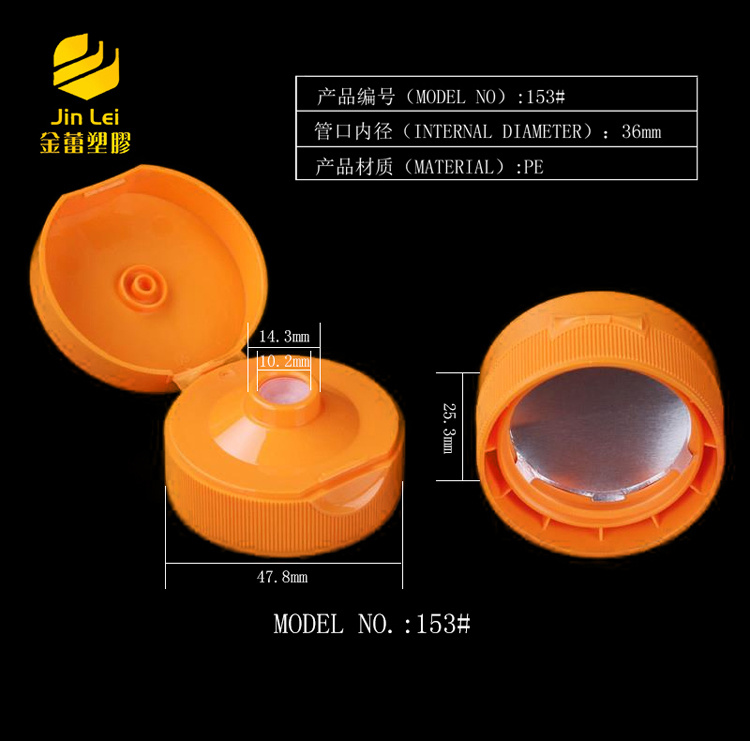

Laundry detergent nozzle, stand-up pouch nozzle, stand-up nozzle, plastic straw cap

Recommended News

Shantou Jinlei Plastics Industrial Co., Ltd.

Phone: 086-754-82511088 / 82511033

Mobile: 8613902732666

Address: 1st and 3rd Floors, Rear Building, Factory No. 35 Shengye Road, Jinping District, Shantou City, Guangdong Province

Email: jl@stjinlei.com

Scan with Mobile

Copyright © Jinlei Plastics