Please tell me how to avoid damage to self-standing spout pouches?

Release Date:

2022-06-02

Currently, are we all familiar with stand-up spout pouches? After all, stand-up spout pouches are now widely used, such as in jelly drinks commonly consumed by children, seasonings in daily life, detergents, and fresh beer, among others. This type of packaging pouch is used in many places. With the widespread application of stand-up spout pouches, more and more issues have been discovered. In today's production of self-made pouches, how can we avoid the problems associated with them?

Currently, we are all familiar with Stand-up Spout packaging bags, right? After all, stand-up spout bags are now widely used, such as in jelly drinks commonly consumed by children, seasonings in daily life, detergents, and fresh beer. This type of packaging bag is used in many places. With the widespread application of stand-up spout bags, more and more issues have been discovered. In today's production of self-made bags, how can we avoid problems with self-made bags? Since stand-up spout bags are made in two stages, each stage requires high process standards. If not properly controlled, quality issues such as bag swelling, bag breakage, and leakage may occur during use. First, in bag making, special attention should be paid to punching and bottom heat sealing, especially in the sealing parts, where it is easy to damage the bag. In addition, stand-up spout bags with a mouth require good opening performance; otherwise, the suction cup is not easy to pull open and install. During bag making, surface static electricity should be eliminated to avoid adhesion between bags, which is unfavorable for the bag-taking process of the sealing machine. Therefore, how to select raw materials and adopt better process operation modes plays a decisive role in improving the overall quality of stand-up bags.

The material selection method for stand-up spout bags is as follows:

1. Selection of composite materials

1. Outer layer

The outer layer is the printing material. Currently, commonly used vertical bag printing materials on the market include ordinary OPP, as well as high-strength, high-barrier materials such as PET and PA, which can be selected according to the situation. For packaging dry fruit solid products, commonly used materials such as BOPP and woven BOPP can be chosen. For packaging liquid products, PET or PA materials are usually selected.

2. Middle layer

The middle layer is usually made of high-strength and high-barrier materials such as PET, PA, VMPET, aluminum foil, etc. In addition, RFID requires that the surface tension of the middle layer material must have good affinity with the adhesive to meet the requirements of composite materials. Stand-up spout

3. Inner layer

The inner layer is the heat-sealing layer. Generally, materials with strong low-temperature heat-sealing properties such as PE, CPE, CPP, etc., are selected. The surface tension of the composite material surface should meet the requirements of composite materials, but the surface tension of the heat shield must be less than 34 mn/m and should have good anti-pollution ability, anti-static ability, and heat-sealing performance.

2. Bag making process requirements

1. Heat sealing temperature

Factors to consider when setting the heat sealing temperature include: 1. Characteristics of the heat sealing material; 2. Film thickness; 3. The number of heat sealing and heat pressing operations and the size of the heat sealing area. Generally, when the same part is heat pressed multiple times, the heat sealing temperature can be appropriately reduced. Stand-up spout

2. Heat sealing pressure

Appropriate pressure must be applied during the heat sealing process to promote adhesion of the heat shield material. However, if the pressure is too high, molten material will be squeezed out, which not only affects the flatness of the bag, fault analysis and troubleshooting, but also affects the heat sealing effect of the bag and reduces the heat sealing strength.

3. Heat sealing time

Heat sealing time is related not only to heat sealing temperature and pressure but also to the performance of the heat sealing material, heating method, and other factors. Specific operations should be adjusted during actual debugging according to different equipment and materials.

4. Heating mode

The heating method of the heat sealing knife during the bag heat sealing process can be divided into single-sided heating and double-sided heating. Obviously, heating on both sides is more effective and practical than heating on one side.

Keywords:

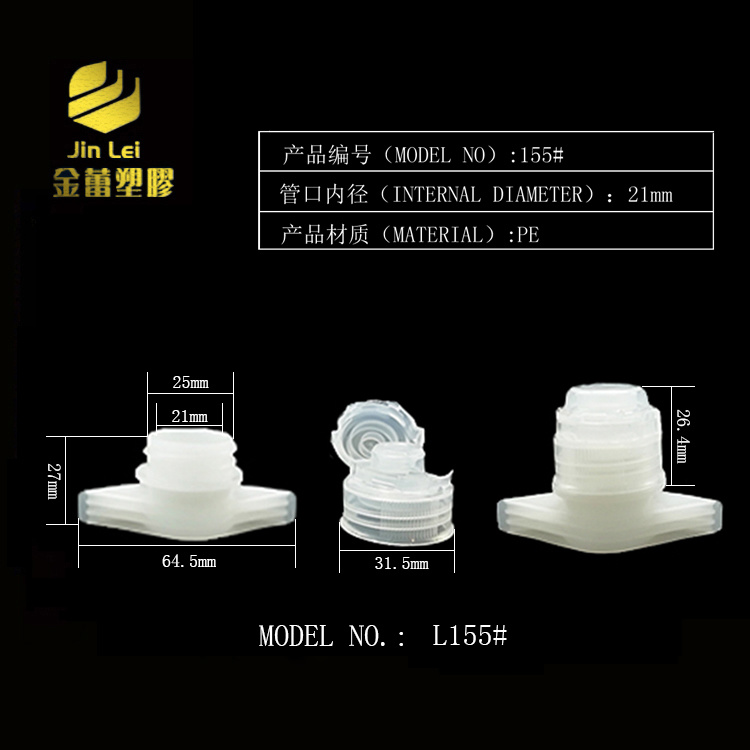

Stand-up pouch spout, stand-up spout, plastic straw cap

Recommended News

Shantou Jinlei Plastics Industrial Co., Ltd.

Phone: 086-754-82511088 / 82511033

Mobile: 8613902732666

Address: 1st and 3rd Floors, Rear Building, Factory No. 35 Shengye Road, Jinping District, Shantou City, Guangdong Province

Email: jl@stjinlei.com

Scan with Mobile

Copyright © Jinlei Plastics